Selecting the best material for a high-speed Printed Circuit Board (PCB) involves a critical trade-off between performance, cost, and manufacturability. The ideal choice depends heavily on the application’s operating frequency, with key material properties like a low and stable Dielectric Constant (Dk) and a low Dissipation Factor (Df) being paramount for maintaining signal integrity. While standard FR-4 is suitable for lower-speed applications, high-speed designs often require advanced laminates such as high-performance FR-4, Rogers materials, Teflon (PTFE), or specialized substrates like Megtron and Isola series to minimize signal loss and ensure reliable performance.

Table of Contents

- Why Material Selection is Critical for High-Speed PCBs

- What are the Key Electrical Properties of High-Speed PCB Materials?

- A Breakdown of Common High-Speed PCB Materials

- How to Choose the Right High-Speed Material for Your Application

- Advanced Considerations in High-Speed Material Selection

- Conclusion: Making the Informed Choice for Your Next High-Speed Design

Why Material Selection is Critical for High-Speed PCBs

In the realm of digital and analog electronics, “high-speed” refers to designs where the integrity of the signal is affected by the physical characteristics of the PCB, such as its layout, vias, and, most importantly, the substrate material. As signal frequencies climb into the megahertz (MHz) and gigahertz (GHz) ranges, the PCB is no longer a simple “connect-the-dots” platform. Instead, it becomes an active component in the circuit, where the laminate material can either preserve or degrade the signal traveling through it. The wrong material choice can lead to a cascade of signal integrity issues, including unacceptable signal loss, data-corrupting reflections, and timing errors, ultimately causing system failure.

The primary challenge with high-speed signals is their sensitivity to the medium through which they propagate. Standard FR-4, the workhorse of the PCB industry, is a glass-reinforced epoxy laminate that offers an excellent balance of cost and mechanical stability for a vast range of applications. However, its electrical properties, particularly its relatively high and frequency-dependent Dk and Df, become a significant liability at high speeds. As frequencies increase, the dielectric losses within FR-4 skyrocket, attenuating the signal to the point where it may become unrecognizable to the receiver. This forces designers to move beyond the familiar and explore a world of specialized materials engineered for high-frequency performance.

What are the Key Electrical Properties of High-Speed PCB Materials?

When evaluating PCB laminates for a high-speed design, engineers focus on a specific set of electrical and thermal properties that directly influence signal behavior and overall board reliability. Understanding these parameters is the first step toward making an informed material selection.

Dielectric Constant (Dk): The Heart of Impedance Control

The Dielectric Constant (Dk), also known as relative permittivity (εr), measures a material’s ability to store electrical energy in an electric field. For high-speed design, its most critical role is in determining the characteristic impedance of a transmission line (trace). A consistent and predictable Dk is essential for maintaining a constant impedance (e.g., 50 ohms) along a trace, which is vital for preventing signal reflections and maximizing power transfer. Any variation in Dk along the signal path will create an impedance mismatch, causing portions of the signal to reflect back to the source, degrading signal quality.

Furthermore, the Dk of many materials, including standard FR-4, changes with frequency. A material with a Dk that is stable across the entire operating frequency spectrum of the signal is highly desirable. This stability ensures that all frequency components of a digital signal travel at nearly the same speed, preventing a form of distortion known as dispersion. High-performance materials are specifically engineered to exhibit a flat Dk response over a wide frequency range.

Dissipation Factor (Df) or Loss Tangent (tanδ): The Enemy of Signal Strength

The Dissipation Factor (Df), often called Loss Tangent (tanδ), quantifies how much of a signal’s energy is absorbed and lost as heat within the dielectric material. This is known as dielectric loss, and it is a major component of a signal’s total insertion loss. In high-speed design, a low Df is non-negotiable. As signals travel along a trace, a high Df material will progressively absorb the signal’s energy, weakening its amplitude. This effect is especially pronounced at higher frequencies and over longer trace lengths.

For multi-gigabit data channels, such as those used in PCIe or 100G Ethernet, minimizing Df is critical to ensuring the signal arrives at the receiver with enough amplitude to be correctly interpreted. Materials are often categorized by their loss characteristics, with terms like “low loss,” “very low loss,” and “ultra-low loss” directly corresponding to their Df values. A material with a Df of 0.01 is considered standard loss, while an ultra-low loss material might have a Df below 0.002.

Thermal Conductivity: Keeping Your Components Cool

High-speed circuits often involve high-power components that generate significant heat. The PCB material’s ability to dissipate this heat is measured by its Thermal Conductivity (k). A material with higher thermal conductivity can more effectively draw heat away from components like processors and FPGAs and spread it to other areas of the board, such as copper planes or heat sinks. This prevents localized hotspots that can degrade component performance and reduce long-term reliability.

While standard FR-4 has poor thermal conductivity, specialized materials, including ceramic-filled laminates or boards with integrated metal cores (Insulated Metal Substrates), are designed specifically for high-power and high-temperature applications. Effective thermal management is not just about component survival; it also helps stabilize the electrical properties (Dk and Df) of the laminate, as they can also vary with temperature.

Coefficient of Thermal Expansion (CTE): Ensuring Structural Integrity

The Coefficient of Thermal Expansion (CTE) describes how much a material expands or contracts with changes in temperature. In a multi-layered PCB, it’s crucial that the CTE of the laminate closely matches the CTE of copper (around 17 ppm/°C). A significant mismatch can cause immense stress on the board during thermal cycling, such as the manufacturing assembly process or normal operation. This stress can lead to plated through-hole (PTH) barrel cracking, via failures, and delamination, compromising the board’s structural and electrical integrity. The CTE in the Z-axis (through the thickness of the board) is particularly important, as excessive expansion can quickly destroy vias.

Moisture Absorption: A Hidden Threat to Performance

A material’s tendency to absorb moisture from the environment can be a hidden source of problems. Water has a very high Dk (around 70), and when absorbed by the PCB laminate, it can significantly alter the material’s effective Dk and Df. This change can shift the impedance of traces and increase signal loss, leading to inconsistent performance based on the ambient humidity. Materials with low moisture absorption rates provide more stable and reliable electrical performance in a variety of environmental conditions.

A Breakdown of Common High-Speed PCB Materials

The market offers a wide spectrum of PCB materials, each with a unique profile of properties, performance, and cost. Understanding the main categories is key to navigating the selection process.

Standard FR-4: The Baseline

FR-4 is the most widely used PCB material due to its low cost and good mechanical properties. However, its Dk is around 4.2-4.8 and its Df is high (around 0.020), making it suitable only for designs operating below approximately 1-2 GHz. Beyond this, its high dielectric loss rapidly attenuates signals, making it an impractical choice for most modern high-speed digital or RF applications.

High-Performance FR-4: A Cost-Effective Upgrade

Recognizing the limitations of standard FR-4, manufacturers developed “high-performance” or “high-speed” FR-4 variants. These materials use an improved epoxy resin system to achieve a lower Df (typically 0.007-0.010) and a more stable Dk. They represent a fantastic middle ground, offering significantly better performance than standard FR-4 without the high cost of more exotic substrates. They are an excellent choice for applications in the 3-5 GHz range, such as USB 3.0 and some PCIe generations.

Rogers Materials: The Industry Benchmark for RF/Microwave

Rogers Corporation is a leading name in high-performance laminates, and their materials are often the go-to choice for demanding RF, microwave, and high-speed digital designs. Materials like Rogers RO4350B and RO4003C are hydrocarbon ceramic laminates known for their extremely stable Dk over frequency and temperature, and a very low Df. They are processed using standard FR-4 fabrication techniques, making them easier to manufacture than PTFE-based materials. They are a staple for applications from 5 GHz to well over 20 GHz.

Teflon (PTFE) Laminates: The Ultimate in Low-Loss Performance

For the highest frequencies (e.g., 20 GHz to 100+ GHz), Polytetrafluoroethylene (PTFE), commonly known as Teflon, offers some of the best electrical properties available. PTFE-based laminates boast an ultra-low Dk (around 2.1) and an exceptionally low Df. This makes them the material of choice for millimeter-wave (mmWave) applications like automotive radar and 5G infrastructure. However, this performance comes at a high cost. PTFE is also a soft material, which makes it challenging to manufacture, requiring specialized fabrication processes.

Megtron & Isola Series: Advanced High-Speed Digital Materials

Companies like Panasonic (Megtron series) and Isola (I-Speed, Tachyon, I-Tera series) offer advanced material systems specifically targeting the challenges of high-speed digital designs. Materials like Panasonic’s Megtron 6 and Isola’s Tachyon 100G are engineered for extremely low loss, low skew, and high-speed signal transmission, making them ideal for high-layer-count backplanes, servers, and networking equipment running at 25 Gbps, 56 Gbps, and even 112 Gbps.

| Material Type | Typical Dk (@10GHz) | Typical Df (@10GHz) | Relative Cost | Best Use Case |

|---|---|---|---|---|

| Standard FR-4 | ~4.5 | ~0.020 | Low | Low-frequency, < 1 GHz, cost-sensitive |

| High-Performance FR-4 | ~3.7 | ~0.009 | Medium | Digital designs up to 5 GHz, PCIe, USB 3.x |

| Rogers RO4350B | ~3.66 | ~0.0037 | High | RF/Microwave, antennas, high-speed digital > 5 GHz |

| Teflon (PTFE) | ~2.1 | ~0.0009 | Very High | mmWave, automotive radar, 5G, satellite (> 20 GHz) |

| Megtron 6 | ~3.6 | ~0.002 | Very High | High-speed servers, networking backplanes (25-112 Gbps) |

How to Choose the Right High-Speed Material for Your Application

Choosing the right material is a systematic process that balances technical requirements with practical constraints. Following these steps can help guide you to the optimal solution.

Step 1: Define Your Operating Frequency and Data Rate

The single most important factor is your maximum operating frequency or data rate. This will immediately narrow down your material options. For a digital signal, a good rule of thumb is to consider its “knee frequency,” which is roughly half the signal’s rise time. This frequency, not just the clock rate, determines the bandwidth your material needs to support. A 1 GHz clock may have frequency components extending to 5 GHz or more, which must be accounted for.

Step 2: Assess Your Signal Loss Budget

How much signal attenuation can your system tolerate? This is your insertion loss budget. A long trace on a large backplane has a much tighter loss budget than a short trace on a small daughter card. Using a signal integrity simulator, you can model the insertion loss for different materials based on their Df and your trace geometry. This analysis will tell you if a lower-loss (and more expensive) material is a necessity or an over-design.

Step 3: Analyze Thermal Management Requirements

Evaluate the heat generated by your active components. If you have high-power devices, the thermal conductivity of the substrate becomes a critical factor. You may need to choose a material with enhanced thermal performance or incorporate thermal management solutions like thermal vias or coin inserts. Don’t forget to consider the operating environment; a board in a sealed, fanless enclosure has vastly different thermal constraints than one in a forced-air system.

Step 4: Balance Performance with Cost and Manufacturability

Finally, weigh the ideal performance against the realities of your budget and manufacturing capabilities. An ultra-low loss PTFE material might be the perfect electrical solution, but its high cost and complex fabrication might make the project unfeasible. Often, the best choice is a material that meets the required specifications with an acceptable margin, rather than the absolute best-performing material available. Always consult with your PCB fabricator early in the design process to ensure they can reliably process the material you are considering.

Advanced Considerations in High-Speed Material Selection

For state-of-the-art designs, a few more nuanced material properties come into play that can make or break performance.

The Glass Weave Effect and Its Impact on Skew

Most laminates are a composite of resin and woven glass fabric. From a trace’s perspective, sometimes it travels over a glass fiber bundle (higher Dk) and sometimes over a resin-filled gap (lower Dk). This inconsistent Dk beneath the trace causes minute variations in signal velocity. For differential pairs, if one trace sees a different glass-to-resin ratio than the other, they will travel at different speeds, creating “skew.” This timing difference can destroy the differential signal. To combat this, designers can use techniques like rotating the layout relative to the weave or, more effectively, selecting materials with a flatter, more uniform glass weave or those that are not glass-reinforced.

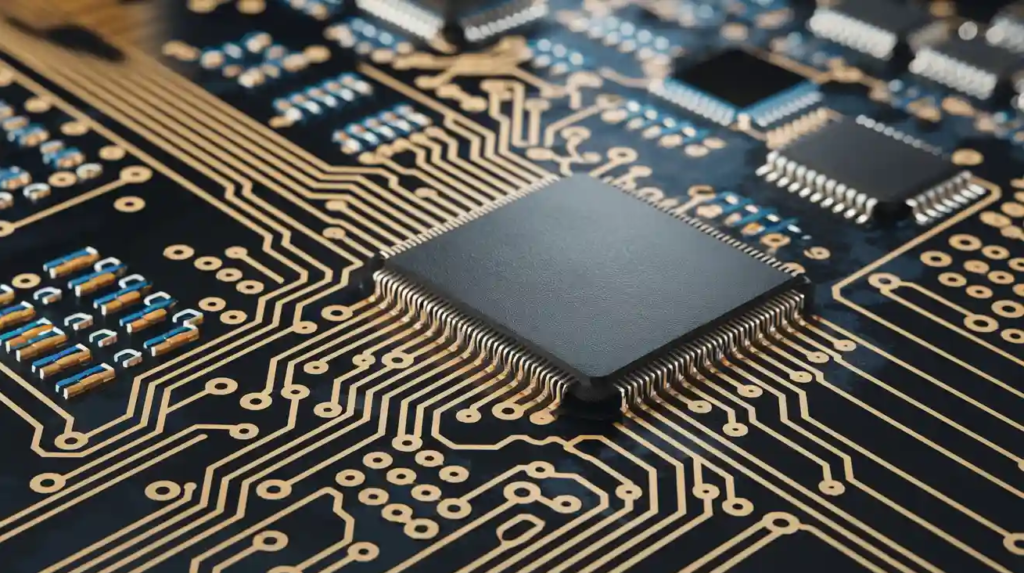

Copper Foil Roughness: A Factor in High-Frequency Losses

At very high frequencies, the “skin effect” forces most of the signal current to travel along the outer surface, or “skin,” of the copper trace. The roughness of the copper foil, particularly on the side bonded to the dielectric, increases the effective path length the current must travel, which in turn increases conductor loss. This loss component becomes very significant at frequencies above 10 GHz. For these applications, specifying laminates with very low profile (VLP) or ultra-low profile (ULP) copper foil is essential to minimize losses.

CAF (Conductive Anodic Filament) Resistance

CAF is a failure mode where a conductive path grows through the dielectric between two oppositely biased copper features, such as two vias. This can cause a short circuit and catastrophic failure. It is more likely to occur in high-humidity environments and with smaller feature spacing. High-performance materials are engineered with resin systems that offer greater resistance to CAF formation, improving the long-term reliability of dense, high-voltage boards.

Conclusion: Making the Informed Choice for Your Next High-Speed Design

The journey to selecting the best material for high-speed PCB design is a meticulous balancing act. There is no single “best” material, only the most appropriate material for your specific application. It begins with a deep understanding of your signal requirements, particularly frequency and loss budget. From there, you must navigate the critical electrical and thermal properties—Dk, Df, CTE, and thermal conductivity—to identify a class of materials that can meet your performance goals. Finally, by weighing these technical needs against the practical constraints of cost and manufacturability, you can make a well-informed decision.

By moving beyond standard FR-4 and leveraging the advanced capabilities of high-performance laminates, engineers can unlock the full potential of their high-speed designs, ensuring robust signal integrity, thermal stability, and long-term reliability in today’s most demanding electronic systems.

High-Speed PCB Design, PCB Materials, High-Frequency PCB Materials, Low-Loss Laminates, Signal Integrity, selecting pcb material for signal integrity, dielectric constant and dissipation factor in pcb, fr-4 vs rogers material for high frequency, cost of high-speed pcb materials, thermal management in high-speed pcb, pcb glass weave effect, Rogers materials, Teflon PCB, Megtron, Isola