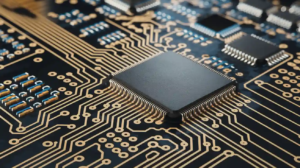

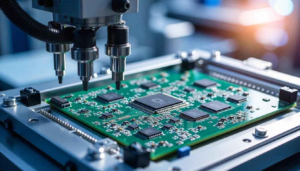

The core difference between a Multilayer PCB and an HDI (High-Density Interconnect) PCB lies in their density and manufacturing technology. While all HDI PCBs are multilayer boards, not all multilayer PCBs are HDI. The distinction comes from HDI PCBs utilizing advanced technologies like microvias, thinner traces, and smaller component pads to pack significantly more functionality into a smaller, lighter, and higher-performing circuit board. Standard multilayer PCBs use traditional mechanically drilled vias and have lower component and routing density in comparison.The core difference between a Multilayer PCB and an HDI (High-Density Interconnect) PCB lies in their density and manufacturing technology. While all HDI PCBs are multilayer boards, not all multilayer PCBs are HDI. The distinction comes from HDI PCBs utilizing advanced technologies like microvias, thinner traces, and smaller component pads to pack significantly more functionality into a smaller, lighter, and higher-performing circuit board. Standard multilayer PCBs use traditional mechanically drilled vias and have lower component and routing density in comparison.The core difference between a Multilayer PCB and an HDI (High-Density Interconnect) PCB lies in their density and manufacturing technology. While all HDI PCBs are multilayer boards, not all multilayer PCBs are HDI. The distinction comes from HDI PCBs utilizing advanced technologies like microvias, thinner traces, and smaller component pads to pack significantly more functionality into a smaller, lighter, and higher-performing circuit board. Standard multilayer PCBs use traditional mechanically drilled vias and have lower component and routing density in comparison.The core difference between a Multilayer PCB and an HDI (High-Density Interconnect) PCB lies in their density and manufacturing technology. While all HDI PCBs are multilayer boards, not all multilayer PCBs are HDI. The distinction comes from HDI PCBs utilizing advanced technologies like microvias, thinner traces, and smaller component pads to pack significantly more functionality into a smaller, lighter, and higher-performing circuit board. Standard multilayer PCBs use traditional mechanically drilled vias and have lower component and routing density in comparison.The core difference between a Multilayer PCB and an HDI (High-Density Interconnect) PCB lies in their density and manufacturing technology. While all HDI PCBs are multilayer boards, not all multilayer PCBs are HDI. The distinction comes from HDI PCBs utilizing advanced technologies like microvias, thinner traces, and smaller component pads to pack significantly more functionality into a smaller, lighter, and higher-performing circuit board. Standard multilayer PCBs use traditional mechanically drilled vias and have lower component and routing density in comparison.The core difference between a Multilayer PCB and an HDI (High-Density Interconnect) PCB lies in their density and manufacturing technology. While all HDI PCBs are multilayer boards, not all multilayer PCBs are HDI. The distinction comes from HDI PCBs utilizing advanced technologies like microvias, thinner traces, and smaller component pads to pack significantly more functionality into a smaller, lighter, and higher-performing circuit board. Standard multilayer PCBs use traditional mechanically drilled vias and have lower component and routing density in comparison.The core difference between a Multilayer PCB and an HDI (High-Density Interconnect) PCB lies in their density and manufacturing technology. While all HDI PCBs are multilayer boards, not all multilayer PCBs are HDI. The distinction comes from HDI PCBs utilizing advanced technologies like microvias, thinner traces, and smaller component pads to pack significantly more functionality into a smaller, lighter, and higher-performing circuit board. Standard multilayer PCBs use traditional mechanically drilled vias and have lower component and routing density in comparison.The core difference between a Multilayer PCB and an HDI (High-Density Interconnect) PCB lies in their density and manufacturing technology. While all HDI PCBs are multilayer boards, not all multilayer PCBs are HDI. The distinction comes from HDI PCBs utilizing advanced technologies like microvias, thinner traces, and smaller component pads to pack significantly more functionality into a smaller, lighter, and higher-performing circuit board. Standard multilayer PCBs use traditional mechanically drilled vias and have lower component and routing density in comparison.The core difference between a Multilayer PCB and an HDI (High-Density Interconnect) PCB lies in their density and manufacturing technology. While all HDI PCBs are multilayer boards, not all multilayer PCBs are HDI. The distinction comes from HDI PCBs utilizing advanced technologies like microvias, thinner traces, and smaller component pads to pack significantly more functionality into a smaller, lighter, and higher-performing circuit board. Standard multilayer PCBs use traditional mechanically drilled vias and have lower component and routing density in comparison.The core difference between a Multilayer PCB and an HDI (High-Density Interconnect) PCB lies in their density and manufacturing technology. While all HDI PCBs are multilayer boards, not all multilayer PCBs are HDI. The distinction comes from HDI PCBs utilizing advanced technologies like microvias, thinner traces, and smaller component pads to pack significantly more functionality into a smaller, lighter, and higher-performing circuit board. Standard multilayer PCBs use traditional mechanically drilled vias and have lower component and routing density in comparison.The core difference between a Multilayer PCB and an HDI (High-Density Interconnect) PCB lies in their density and manufacturing technology. While all HDI PCBs are multilayer boards, not all multilayer PCBs are HDI. The distinction comes from HDI PCBs utilizing advanced technologies like microvias, thinner traces, and smaller component pads to pack significantly more functionality into a smaller, lighter, and higher-performing circuit board. Standard multilayer PCBs use traditional mechanically drilled vias and have lower component and routing density in comparison.The core difference between a Multilayer PCB and an HDI (High-Density Interconnect) PCB lies in their density and manufacturing technology. While all HDI PCBs are multilayer boards, not all multilayer PCBs are HDI. The distinction comes from HDI PCBs utilizing advanced technologies like microvias, thinner traces, and smaller component pads to pack significantly more functionality into a smaller, lighter, and higher-performing circuit board. Standard multilayer PCBs use traditional mechanically drilled vias and have lower component and routing density in comparison.The core difference between a Multilayer PCB and an HDI (High-Density Interconnect) PCB lies in their density and manufacturing technology. While all HDI PCBs are multilayer boards, not all multilayer PCBs are HDI. The distinction comes from HDI PCBs utilizing advanced technologies like microvias, thinner traces, and smaller component pads to pack significantly more functionality into a smaller, lighter, and higher-performing circuit board. Standard multilayer PCBs use traditional mechanically drilled vias and have lower component and routing density in comparison.The core difference between a Multilayer PCB and an HDI (High-Density Interconnect) PCB lies in their density and manufacturing technology. While all HDI PCBs are multilayer boards, not all multilayer PCBs are HDI. The distinction comes from HDI PCBs utilizing advanced technologies like microvias, thinner traces, and smaller component pads to pack significantly more functionality into a smaller, lighter, and higher-performing circuit board. Standard multilayer PCBs use traditional mechanically drilled vias and have lower component and routing density in comparison.The core difference between a Multilayer PCB and an HDI (High-Density Interconnect) PCB lies in their density and manufacturing technology. While all HDI PCBs are multilayer boards, not all multilayer PCBs are HDI. The distinction comes from HDI PCBs utilizing advanced technologies like microvias, thinner traces, and smaller component pads to pack significantly more functionality into a smaller, lighter, and higher-performing circuit board. Standard multilayer PCBs use traditional mechanically drilled vias and have lower component and routing density in comparison.